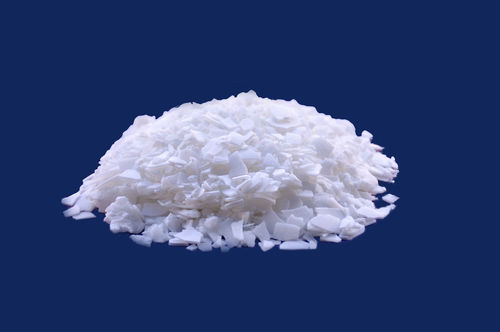

PE Wax

116 INR/Kilograms

Product Details:

- Smell Mild

- Usage & Applications Industrial

- Product Type PE Wax

- Shape Granules

- Chemical Name Polyethylene Wax

- CAS No 9002-88-4

- Classification Other

- Click to View more

X

PE Wax Price And Quantity

- 116 INR/Kilograms

- 1000 Kilograms

PE Wax Product Specifications

- Wax

- Polyethylene Wax

- Granules

- Other

- Industrial

- Mild

- 9002-88-4

- White

- PE Wax

PE Wax Trade Information

- KOLKATA

- 100000 Kilograms Per Day

- 1 Week

- Yes

- Contact us for information regarding our sample policy

- 25 kgs Bags

- All India

Product Description

PE Wax

The offered PE wax is made available by us for use in commercial and industrial applications. The offered wax is typically used as additives to modify properties of compounds in a wide variety of applications. It has a high melting point and has an excellent thermal stability. It is chemical resistant and is very compatible with other kind of wax varieties. The offered PE wax is derived from ethylene through a process called polymerization. It finds applications such as blends, plastic additives and rubber manufacture. It is very efficient and provides the required heat resistance to various compounds and materials.

We have emerged as one of the most prominent names in the industry for the manufacturing and supplying a wide range of chemicals and Industrial Waxes like Polyethylene Wax. The wax offered by us is widely applicable in the industry for various purposes. We do not compromise in terms of quality and so we use high grade basic chemicals for the processing of these waxes that ensures reliability.

Property

White powdery, lumpy, or flaky product, non-toxic, concentrated distribution of molecular weight, specific gravity about 0.94 with high softening point but low fusion viscosity.

Applications

- Polyethylene Wax (PE-Wax) is used as processing auxiliary for PVC pipes, special-shaped materials, film, wire and cable and other plastics and rubber. Polyethylene Wax (PE-Wax) is also used as the lubricant and demoulding agent of polyolefins and PVC.

- Polyethylene Wax (PE-Wax) can improve the fluidity of polyethylene, polypropylene and ABS and the demoulding property of polymethyl methacrylate and polycarbonate.

- For PVC, Polyethylene Wax (PE-Wax) has better internal lubrication as compared with other external lubricants. Polyethylene Wax (PE-Wax) can be used as lubricant and dispersing agent for plastics color master to improve the dispersion of filler or pigment.

- Polyethylene Wax (PE-Wax) is also used as the processing modifier for plastics and elastomers, the ink paste polisher, paper coating and in candle.

Specifications of Polyethylene Wax | ||

| ITEM NO. / SPECIFICATIONS | GCC- 40 | GCC- 70 |

| Appearance | White particle, Flakes | White particle, Granules |

| Viscosity @ 149o C | 10 -40 cps | 35 - 65 cps |

| Melting Point (oC) | 110 -115 | 100 -105 |

| Density (gms/cc) | 0.94 | 0.93 +/- 0.1 |

| Melt Peak (oC) | 110 | 92 |

| Flash Point (oC) | Min 210 | Min 210 |

| Molecular Weight | 1500 | 1500 |

| Penetration @ 25oC | 4.00 - 5.00 | 2.00 -4.95 |

| Packages | 25 Kgs/bag | 25 Kgs/bag |

| Colour | White / As per Sample | White / As per Sample |

| 20'' FCL | 14 Tonnes (Without Pallet) | |

Situated in Kolkata, we are reckoned as a leading manufacturer and exporter of PE Wax or polyethylene wax. The necessary details of PE Wax include -

Technical Specification

| Properties | |

| Viscosity @ 149 Deg. C, cps | 40 ~ 60 |

| Mettler Drop Point, Deg. C | 105-110 |

| Density, gms/cc | 0.94 |

| Molecular Weight (Avg.) | 1500 |

| Colour | As per Sample |

Application Summary

| Application | Attributes |

| Asphalt | Softening point & hardness modifier. Flow agent. |

| Cable Filling | Gelling agent & improved heat resistance. |

| Colour Concentrate | Improvement of pigment wett ability and dispersion. |

| Corrugated Board | Enhancement of surface for scuff & blocking resistance. |

| Expanded PS Foam | Lubricant & blowing agent dispersant. |

| Hot Melt Adhesive | Viscosity control & improved heat resistance. |

| Hot Melt Road Marking | Viscosity reduction, processing benefits, heat resistance. |

| Paint | Flatting, abrasion & scratch resistance, anti-blocking. |

| Paper Coating | Adjustment of slip & hardness properties. |

| Polish | Gelling agent. Good scuff, slip & black mark resistances. |

| Printing Ink | Excellent rub resistance. |

| PVC Compounding | Efficient external lubricants at low concentrations. |

| Rubber Processing | Superb processing aid & lubricant. |

Versatility in Industrial Applications

PE Wax is multifunctional, playing a crucial role in several industries. Its main uses include serving as a dispersant, lubricant, and mold release agent in the plastics and rubber sectors. Additionally, it is highly valued in the production of inks and coatings where it imparts improved scuff resistance and gloss. Its adaptability and compatibility with a wide range of materials make it indispensable for industrial operations.

Product Characteristics and Formulation Benefits

This white, granular polyethylene wax stands out for its mild smell and easy handling. It is supplied in granule form to facilitate accurate dosing and homogenous mixing in industrial processes. PE Wax is chemically inert, providing reliable performance even under demanding manufacturing conditions. The consistency and stability of this wax simplify processing and lead to higher quality end products.

FAQs of PE Wax:

Q: How is Polyethylene Wax (PE Wax) utilized in industrial applications?

A: PE Wax is commonly used as a processing aid, lubricant, and dispersing agent in plastics and rubber manufacturing. It is also added to inks and coatings to enhance properties like gloss, scratch resistance, and flow.Q: What are the benefits of using PE Wax in manufacturing processes?

A: Utilizing PE Wax brings benefits such as improved process efficiency, enhanced surface finish, better mold release, and increased durability in finished products. Its stability and inert nature ensure consistent results.Q: Where is this Polyethylene Wax primarily supplied from in India?

A: Polyethylene Wax is distributed by various reputable exporters, importers, manufacturers, and suppliers throughout India, catering to the needs of diverse industrial clients.Q: When should PE Wax be added during the manufacturing process?

A: PE Wax is usually incorporated during the compounding or mixing stage, depending on the application, to ensure it disperses evenly and delivers maximum performance in the final product.Q: What is the typical physical appearance and smell of PE Wax?

A: PE Wax is typically supplied in the form of white granules and has a mild smell, making it suitable and user-friendly for various industrial processing environments.Q: How is Polyethylene Wax processed or blended into products?

A: PE Wax is blended into the host materials using industrial mixers, often at elevated temperatures, to ensure uniform dispersion and optimal effectiveness in the end product.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese