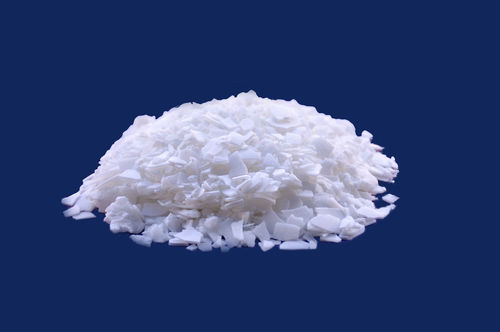

Polyethylene Wax Flakes

116 INR/Kilograms

Product Details:

- Product Type Polyethylene Wax Flakes

- Shape Flakes

- Usage & Applications Industrial

- Chemical Name Polyethylene Wax

- CAS No 9002-88-4

- Classification Other

- Color White

- Click to View more

X

Polyethylene Wax Flakes Price And Quantity

- 1000 Kilograms

- 116 INR/Kilograms

Polyethylene Wax Flakes Product Specifications

- Polyethylene Wax Flakes

- Other

- Polyethylene Wax

- Flakes

- Wax

- White

- Industrial

- 9002-88-4

Polyethylene Wax Flakes Trade Information

- KOLKATA

- 100000 Kilograms Per Day

- 1 Week

- Yes

- Contact us for information regarding our sample policy

- 25 kgs Bags

- All India

Product Description

The offered Polyethylene Wax Flakes are made available by us for use in various commercial and industrial applications. The offered flakes have high use in various places as it has a Softening point and can be used as a hardness modifier. It can be used as a flow agent. The offered wax is a Gelling agent and has an improved heat resistance. The offered Polyethylene Wax Flakes provide Improvement of pigment wet ability and dispersion in the color concentrate. It also provides Enhancement of surface for scuff & blocking resistance. It also provides Viscosity control & improved heat resistance.

Technical Specification :

| Properties | |

| Viscosity @ 149 Deg. C, cps | 40 60 |

| Mettler Drop Point, Deg. C | 105-110 |

| Density, gms/cc | 0.94 |

| Molecular Weight (Avg.) | 1500 |

| Colour | As per Sample |

Application Summary :

| Application | Attributes |

| Asphalt | Softening point & hardness modifier. Flow agent. |

| Cable Filling | Gelling agent & improved heat resistance. |

| Colour Concentrate | Improvement of pigment wettability and dispersion. |

| Corrugated Board | Enhancement of surface for scuff & blocking resistance. |

| Expanded PS Foam | Lubricant & blowing agent dispersant. |

| Hot Melt Adhesive | Viscosity control & improved heat resistance. |

| Hot Melt Road Marking | Viscosity reduction, processing benefits, heat resistance. |

| Paint | Flatting, abrasion & scratch resistance, anti-blocking. |

| Paper Coating | Adjustment of slip & hardness properties. |

| Polish | Gelling agent. Good scuff, slip & black mark resistances. |

| Printing Ink | Excellent rub resistance. |

| PVC Compounding | Efficient external lubricants at low concentrations. |

| Rubber Processing | Superb processing aid & lubricant. |

Versatile Industrial Applications

Polyethylene Wax Flakes stand out for their adaptability across various industries. Their unique properties make them ideal for use in plastics processing, paint and coating formulations, hot-melt adhesives, and printing inks. These flakes improve the end products durability, surface finish, and processability.

Premium Quality from Trusted Source

Sourced and processed under strict quality controls, our Polyethylene Wax Flakes deliver consistent performance. As reliable exporters, importers, manufacturers, and suppliers from India, we ensure our product meets rigorous industrial standards, catering to both domestic and international markets.

FAQs of Polyethylene Wax Flakes:

Q: How are Polyethylene Wax Flakes typically used in industrial applications?

A: Polyethylene Wax Flakes are added to plastics, coatings, and adhesives to enhance lubrication, improve surface gloss, and increase heat resistance. Their flaked form ensures easy mixing and uniform distribution in manufacturing processes.Q: What is the benefit of using white Polyethylene Wax Flakes in manufacturing?

A: The white color ensures that the wax does not alter the appearance of finished products. Additionally, its high chemical and thermal stability enhances product durability and performance across varied applications.Q: When should Polyethylene Wax Flakes be incorporated during production?

A: They are generally integrated at the compounding or blending stage, allowing thorough mixing with other raw materials. This facilitates even dispersion and maximizes the functional benefits of the wax flakes.Q: Where can you source high-quality Polyethylene Wax Flakes in India?

A: You can obtain premium Polyethylene Wax Flakes from established exporters, importers, manufacturers, and suppliers in India who adhere to stringent quality standards for both domestic and international markets.Q: What is the process for manufacturing Polyethylene Wax Flakes?

A: The flakes are produced by polymerizing ethylene under controlled conditions, followed by refining and cooling, which creates the characteristic flake shape for efficient handling and processing.Q: How do Polyethylene Wax Flakes improve the properties of plastics and coatings?

A: They act as excellent lubricants and dispersing agents, reducing friction during processing, enhancing gloss, and boosting scratch resistance in plastics and coatings, thus improving both appearance and functionality.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese